Description

Composition in %

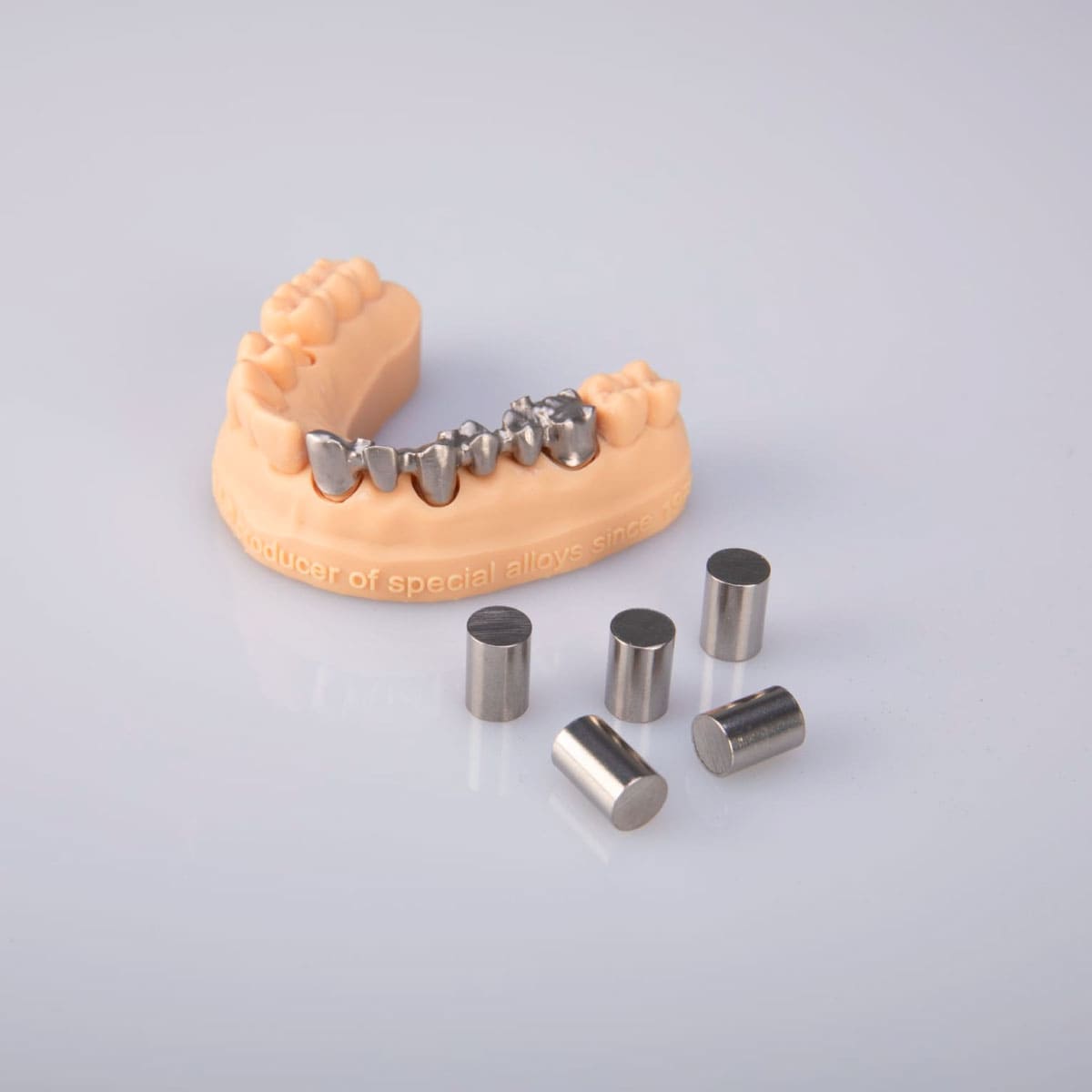

Cobalt (Co) 62,5 % Chrome (Cr) 28,5 % Molybdenum (Mo) 4% Tungsten (W) 3% Others Nb, Fe

Physical and mechanical features

| Solidus-liquidus temperature | 1369 ÷ 1471 °C |

| Thermal expansion coefficient | (25 ÷ 500 °C) 14,5 x 10-6 K-1 – (25 ÷ 600 °C) 14,7 x 10-6 K-1 |

| Melting point | 1340 °C |

| Density | 8,2 g/cmc |

| Vickers hardness | 302 HV10 |

| Percentage elongation at fracture | 5% |

| Yield load strength | (Rp0.2) 535 MPa |

| Modulus of elasticity | 195 GPa |

| Ions release in 7 days | – |

| Maximium cooking temperature | 980°C |

| Colour | White |

CE 0425 ACCORDING TO: ISO 9693-1, ISO 22674